We offer a variety of polymer extruder screens to meet your specific requirements of extruding process and polymer melt filtration applications.

Our polymer extruder screen is made of high-quality corrosion-resistant materials (galvanized copper, stainless steel, and nickel alloy). A wide range of micron ratings are available to meet different filtration demands.

Polymer extruder screens are widely used for filtration and co-mingling processes in the production of various viscous flow materials and products such as plastics, chemical fibers, rubber, hot melt adhesives, finishing materials, blends, etc. It can effectively block foreign matter from being mixed in the final plastic and rubber extrusion process and provide a clean, viable extrusion.

As we use high-quality, non-toxic raw materials, our polymer extruder screens can also be used in the food and beverage industry.

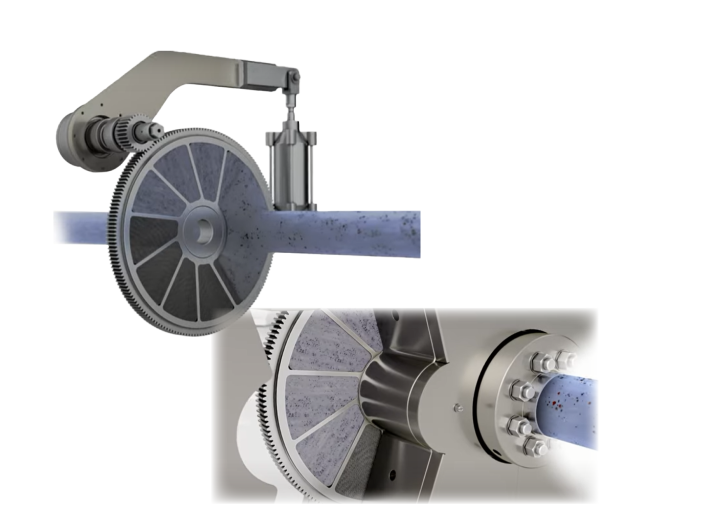

Working Principle

The filter disk is equipped with a large under of polymer extruder screens. The filtration time or pressure value is preset. The melt enters from the inlet, the screen at the inlet starts to filter impurities and gel impurities are trapped on the screen surface. When the filtration time or pressure reaches the preset value, the filter disk begins to rotate. The clean part of the screen rotates to the inlet and starts to filter impurities, meanwhile the screen saturated with impurities moves to the screen change port. The turntable stops rotating, the screen change port opens, the screen with impurities is removed and replaced with a clean screen. In this process, the resting part of the screen keeps operating smoothly, thus realizing continuous operation.

Structure

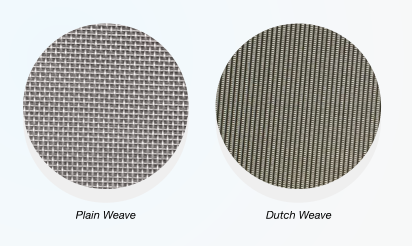

Polymer extruder screen is generally made of plain weave and Dutch weave wire mesh. The plain weave wire mesh features simple structure, economic to process and high cost-effectiveness and can meet the most filtration requirements of plastic products and rubber industries. In a filter, the Dutch weave wire mesh plays the role of fine filtration without requiring a backup filter screen, featuring high strength, high load capacity, simple structure and long service life.

Manufacturing Process

Polymer extruder screen is generally made of plain weave or Dutch weave wire mesh.

The plain weave wire mesh features a simple structure, is economical to process and highly cost-effective, and can meet the most demanding filtration requirements of plastic products and rubber industries. In a filter, the Dutch weave wire mesh plays the role of fine filtration without requiring a backup filter screen, featuring high strength, high load capacity, a simple structure and long service life.

Material

In terms of the filter media selection, the working conditions of the polymer extruder screen shall be taken into full consideration. For example, we will choose stainless steel wire mesh in some PVC production lines or other applications that need to avoid rust, and nickel alloy wire mesh is used to avoid corrosion caused by fluoropolymers or PVDC.

Shape

Our polymer extruder screen can be designed into different shapes to meet the needs of different extruders.

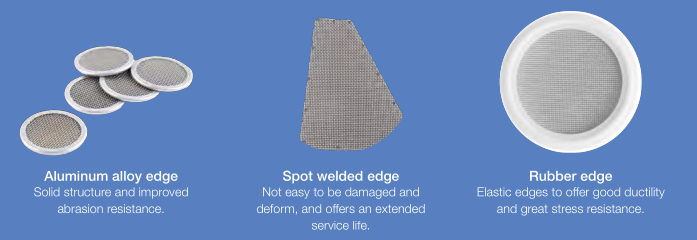

Edge Processing

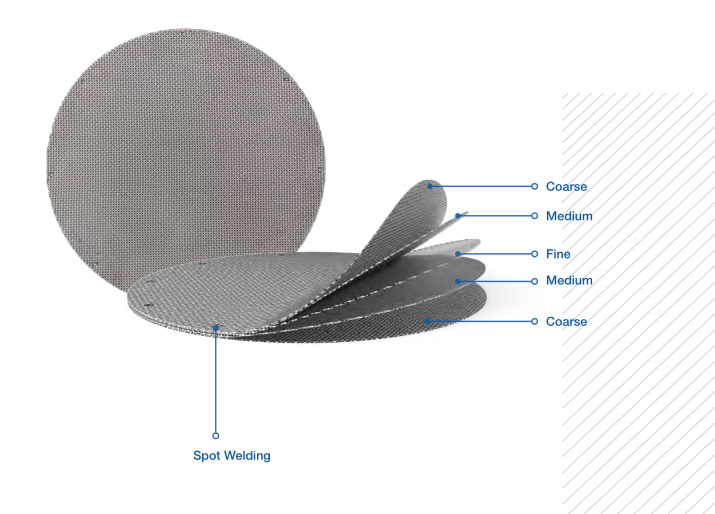

We offer metal (stainless steel or aluminum alloy) edges, spot welded or rubber edges to reduce the wear and tear of the polymer extruder screen, improve the durability and strength of the screen, ensure the stability of the overall structure, and extend the life of the screen. Other edges are available upon request.

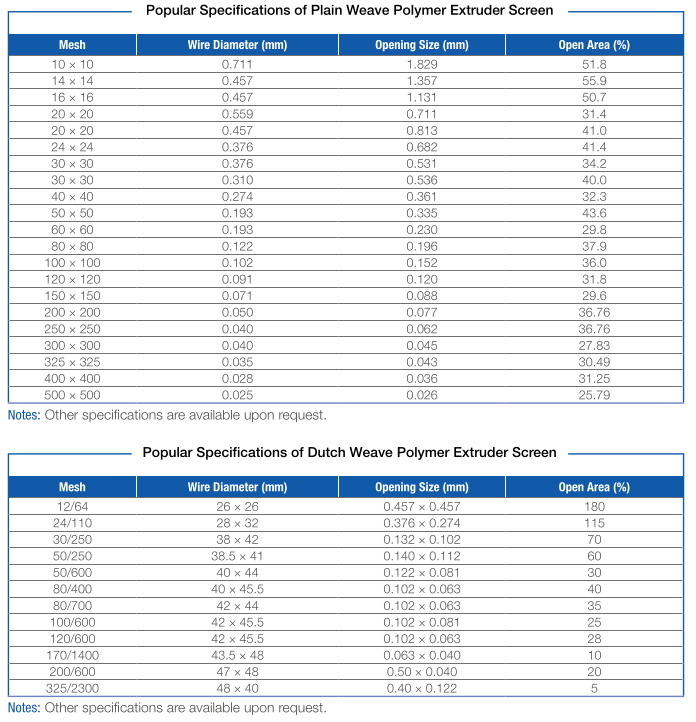

Specification

To ensure the polymer extruder screen offers the most effective filtration and extrusion when you choosing the product, the following aspects shall be taken into consideration: weave type (plain weave or Dutch weave), mesh count (the number of mesh per square inch), wire diameter and open area.